High Vacuum Exhaust/Bake Stations

Custom vacuum pump stations with optional bake-out ovens. We regularly manufacture purpose-built manifolds to work with our customer's parts. Get the best possible machine for your process. We do nearly all of the fabrication and construction in-house and can pass the savings on to the customer. See a few examples below of existing equipment we have built:

Auto Coater

Automatic vapor deposition machine.

With a rotating parts carousel, microprocessor controls and multiple sources, this equipment will reliably and automatically coat parts with silver and chrome in one process. Pushbutton solution. We have built many of these machines that have been in use daily for decades.

450° High Vacuum Oven

For bulk out-gassing

This machine is a simple vacuum chamber (approximately the same size as our model G-Furnace) that reaches 450° Celcius at an eight-scale vacuum. The majority of the chamber is within the frame and the lid is watercooled, making this completely safe to work around during normal operation. Fully automatic pumpdown, heating/cooldown profile, and vent to atmosphere. A very cost effective workhorse for outgassing of parts that do not require the higher temperature of our normal furnaces.

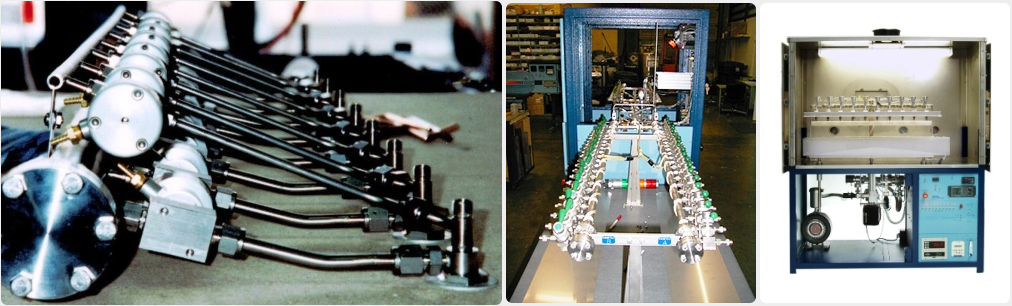

Eight Element Burn-in Station

Complete QA Solution

This machine has eight high-current feedthroughs in a high vacuum watercooled chamber, connected to individual rack-mounted power supplies controlled by a dedicated PC. The customer is able to excite and degas their parts in high vacuum, while also running it through desired stress tests and normal operations. By "breaking-in" and thoroughly testing these particular parts and eliminating potential problems before final assembly, the customer is able to save considerably on their production costs.

GVAC Autoloader

Fully robotic solutions

A fully robotic high vacuum auto-loading furnace. Capable of processing up to five different batches up to 1200°C in high vacuum (with different heating profiles if necessary) in the same run. Parts sit in molybdenum baskets on a revolving carousel and are loaded into the furnace chamber via robotic arm. Completed parts return to the carousel to cool at room temperature in high vacuum chamber while the remaining parts run.

Shielded Pump And Bake Station

Evacuate, excite and bake-out x-ray parts

An ultra-high vacuum pump and bake station for x-ray tubes. Large shielded box with leaded windows constructed around the manifold to allow the user to safely excite their parts during the process. 3-stage pumpdown (dry scroll pump, turbomolecular pump, and ion pump) with heating tapes everywhere to easily achieve ultra-high vacuum.

Thermocouple Calibration Station

Exceptional Uniformity and Ease of Use

With 7 test ports up to 1/4" diameter, this machine will test thermocouples with an accuracy of ±.25°C. Two ports for inserting reference thermocouples or an optical pyrometer for a baseline to test from. Simple microprossesor controls are robust, easy to use, and create a highly repeatable environment.