Photo and Video Gallery

Check out some of our equipment in action

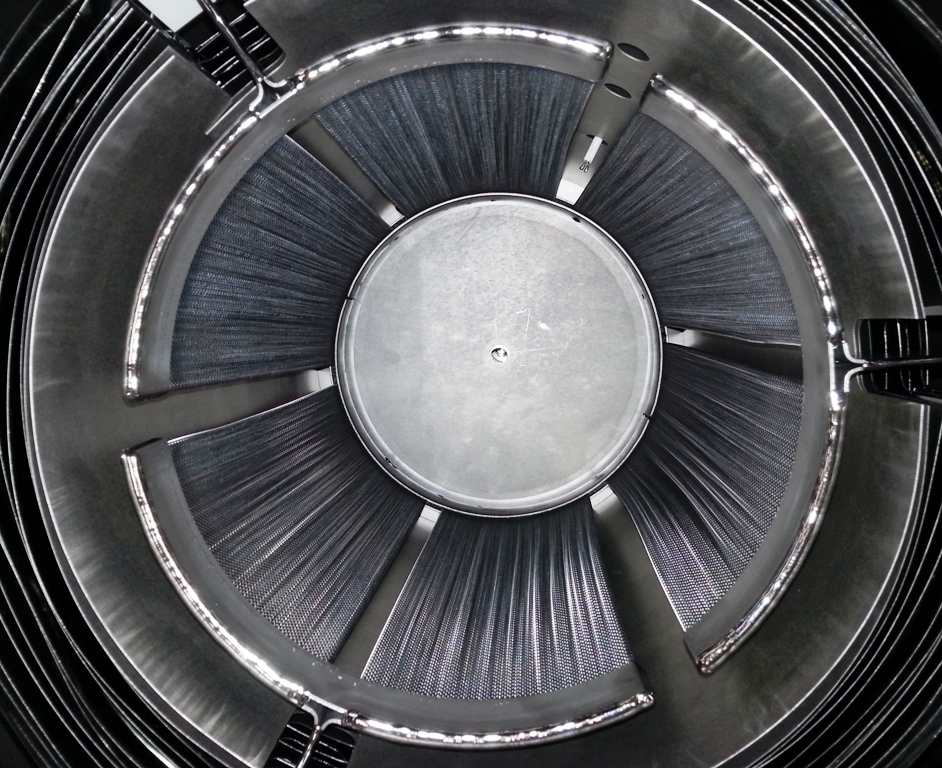

A tungsten mesh heating element for our 2000°+ model B hot zone. While more expensive, these mesh style elements are more robust than sheet elements and typically last much longer.

Timelapse footage of a cusil braze in wet hydrogen in a front-loading model 'G' furnace, as seen through our standard sight-port

A standard B furnace hot zone with molybdenum wire heating elements.

A demonstration of the durability of our heating elements with two different B16 Hydrogen furnaces. These hot zones have been up to 1600°C several times and remains robust. No need to worry about operator error causing a costly and time consuming mistake.

Our molybdenum sheet element style hot zone. This furnace has superior temperature uniformity but is not as robust as our more popular moly wire style.

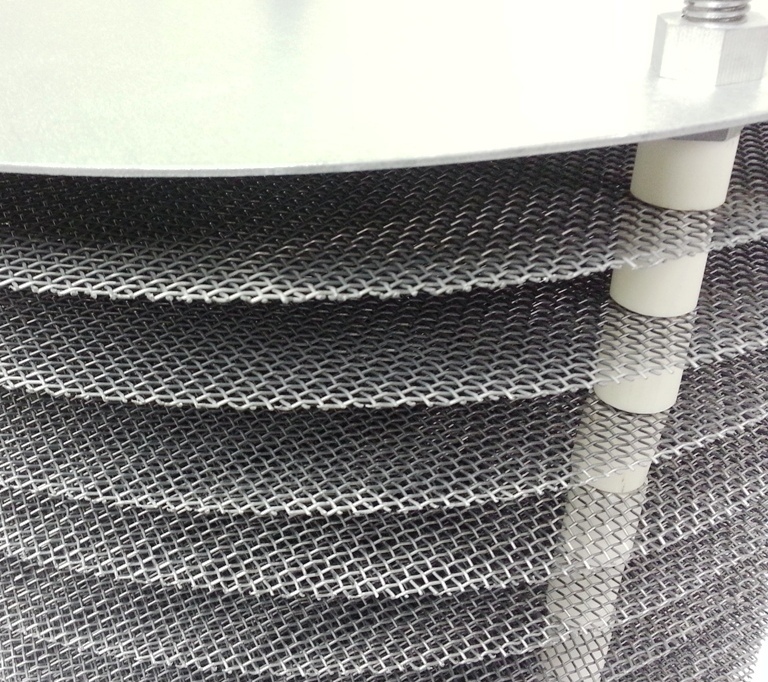

A close-up of a high temperature rack made from pure molybednum plates, mesh, all-thread and nuts, with high alumina ceramic spacers.

Ideal wall hookups for most of our furnaces

Large blowoff neck on the rear of a high-pressure hydrogen B Furnace

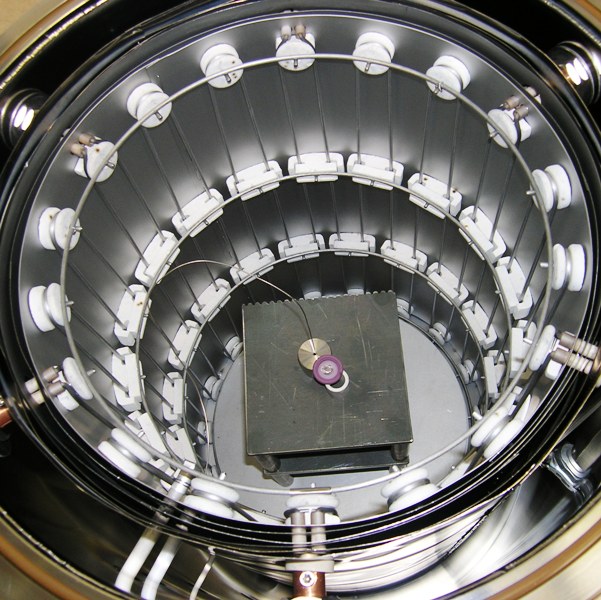

A hot-zone for a front loading model 'G' Furnace with parts and survey thermocouples. These simple molybdenum hot zones can last decades with proper care.

Our furnaces are quiet and safe enough to feel comfortable working right along side of

A Top Loading 1600°C G-Furnace. This furnace is identical to our typical front-loading model 'G' furnace except that it loads vertically rather than horizontal.