Camco Hydrogen Furnaces

By operating in hydrogen or any reducing/inert atmosphere up to 2100°C, Camco's positive pressure coldwall furnaces are an ideal solution to many high temperature processes that require an oxygen-free or reducing environment. Easily and reliably ramp up to the desired temperature in minutes or days, depending on your requirements. Additionally, optional heated bubblers and dewpoint monitors can be used to easily achieve and control the higher dewpoints necessary for metalizing ceramics. Most of our models will roll through a standard interior door frame with little to no deconstruction. All our furnaces are fully automatic. One button push performs:

Request a Quote Today »

→ Purge (Fully evacuate with vacuum pump, and displace atmosphere inside chamber with nitrogen)

→ Process gas fill with mass flow controller (H2, N2, or mixture)

→ Bubbler for humidification of process gas (Optional)

→ PID controlled ramp(s) to target temperature

→ Soak

→ Cooldown

→ Post purge (displace process gas inside chamber with nitrogen for safe opening)

Hydrogen furnaces offer a lower cost alternative to high-vacuum furnaces if the process can allow for it. They are self cleaning, inexpensive to run and maintain, and process cooling in hydrogen is quick and controllable.

Though built specifically to run safely in a wet or dry hydrogen atmosphere, these furnaces can run just as well in any high-purity inert or reducing gas types such as:

•Argon

•Nitrogen

•Helium

•Forming Gas (H5N)

•Dissociated Ammonia

•or any combination.

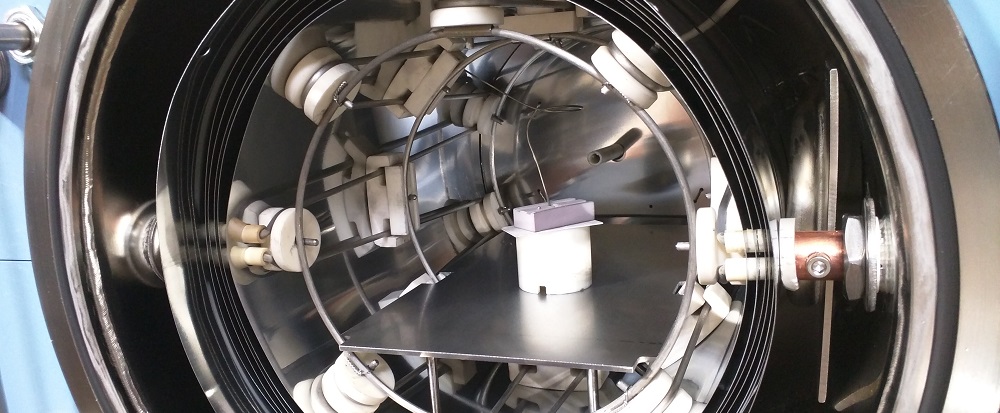

Model "G" Hydrogen Furnace

39" Width x 26" Depth x 20" Height

( 100cm Width x 66cm Depth x 51cm Height )

( ø15.2cm X 25.4cm Depth )

Model "B" Hydrogen Furnace

- Medium Chamber Size

- Ideal for small part production

- Our most popular product to date.

- Footprint:

65" Width x 28.12" Depth x 50" Height

( 165cm Width x 72cm Depth x 127cm Height ) - Work Zone: ø12" X 18" Height

( ø30.5cm X 45.7cm Height )

Model "J" Hydrogen Furnace

- Large Chamber Size

- Smooth hoist lifts chamber over parts

- Ergonomic loading height

- Footprint:

54" Width x 34" Depth x 121"+ Height

( 138cm Width x 87cm Depth x 307cm Height ) - Work Zone: ø18-20" X 24-48" Height

( ø45cm-50.8cm x 61cm-122cm Height )

Custom "J" Chambers

- Extra Large / Long Chambers

- Built specifically to fit your parts

- Smooth ball screw or winch operated hoist

- Often used for final brazing of traveling-wave tubes

- Footprint: Varies Greatly

(Refer to Model "J" for estimates on dimensions) - Work Zone: Up To 80" Height @ ø18-20"

( Up to 203cm Height @ ø45cm-50.8cm )

GloveBox Retrofits

- Add a G Furnace to a controlled atmosphere glovebox

- Can either work with a stock vendor-supplied side panel, or create from scratch exactly to customer specifications

- Every unit is custom built to order. We can use any of our front-loading Hydrogen or High Vacuum furnaces

- Please call or email us to discuss more about your requirements

Camco Furnace Process and Safety Features

All Camco hydrogen furnaces include a wide array of standard features to ensure safety as well as process repeatability.

Request a Quote or More Info Today »

• Oxygen sensor, automatic leak tests, burnoff sensor, multiple thermostats, TC burnup protection, and many more

• Advanced process controls including cascade and guarantee soak instructions

• Includes 3 standard thermocouples for element temperature, flexible survey TC, and high temperature monitor

• Temperature triggers to ensure processed parts reach specific conditions EVERY time

• Data and Event logs with timestamps, with clear and concise alarm messages

• FTP and webserver for remote monitoring (no remote control - local operators only for safety)

• Burnoff column standard - please inform Camco if needing to vent the exhaust.

• Camco furnaces can be ordered to operate on nearly any power input. Other options include more survery TCs, gas humidifier (bubbler), rough vacuum and partial pressure.