High Temperature and High Vacuum Experts

Manufacturers of quality metallurgical and heat treating equipment since 1984. Camco's furnaces are extremely efficient and have the smallest overall equipment size per work-zone volume on the market. Most of our models will roll through a standard door frame with little or no deconstruction. We provide the best warranty in the industry and nearly all repairable parts are stocked for immediate replacement. From its manufacturing facility in the San Francisco Bay Area, Camco supports businesses in a broad range of industries located all around the world.

Hydrogen Furnaces

Workhorses of the Industry

Camco offers a large range of standard hydrogen/inert atmosphere furnace models, all equipped with the same outstanding user-friendly control features. Efficient to run, simple to program, built to the highest standards and have a low cost of ownership compared to competitors. Exceeds all industry safety standards. Less expensive than a high vacuum furnace if inert and reducing atmospheres can work for your processes.

Vacuum Furnaces

Ultra Clean and Reliable

Have the confidence to run parts in 10-7 torr pressure ranges up to 2000°C at the push of a single button. Like our hydrogen furnaces, Camco's vacuum furnaces are available in many sizes and models, all equipped with the same outstanding user-friendly control features. Standard turbomolecular pumps are dependable and nearly maintenance-free with proper care. Though most commonly used for clean firing and annealing, our vacuum furnaces are becoming more frequently used for active metal (ABA) brazing, which is an excellent alternative to ceramic metalizing.

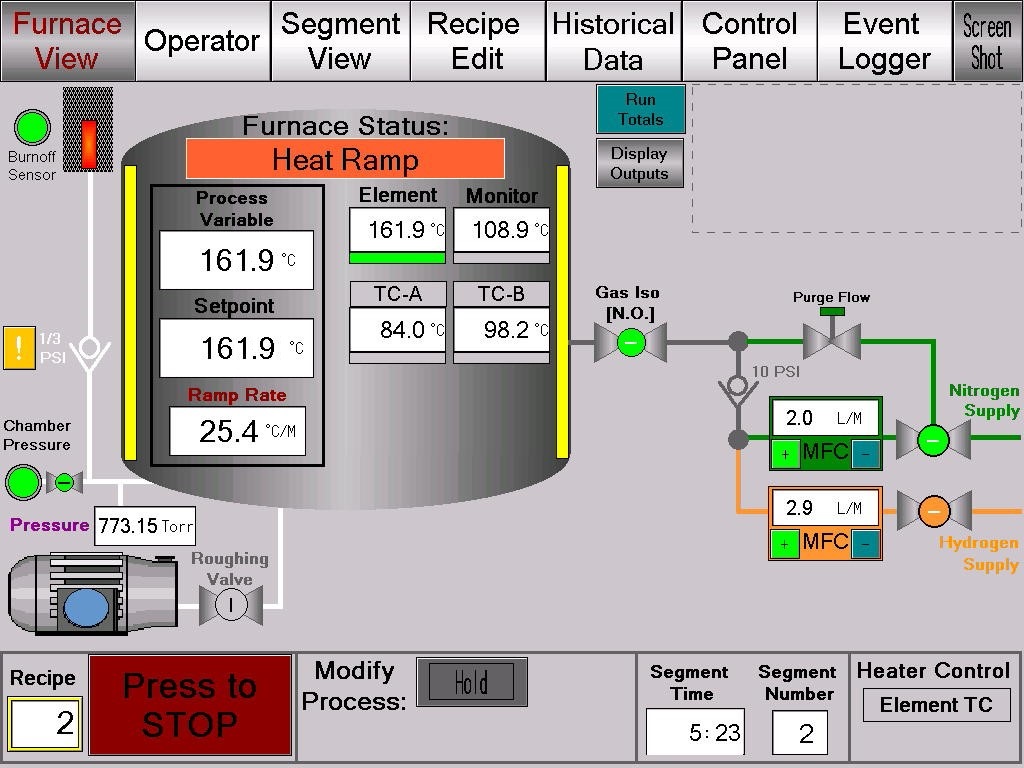

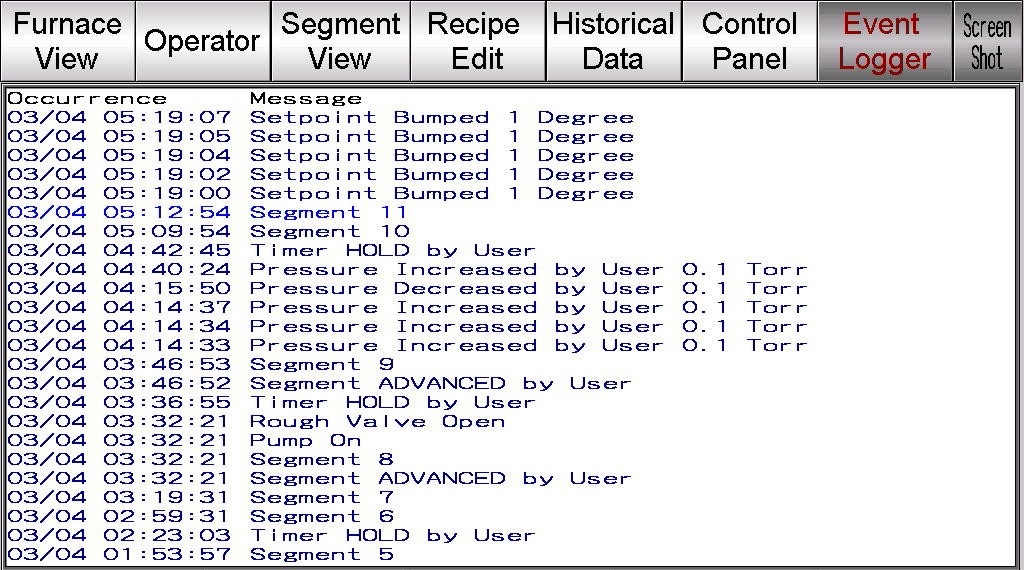

Standard Touchscreen Controllers

Powerful and Easy to Use

Since 2021, all Camco furnace have been built standard with modern touchscreen controllers. This new controller was developed in-house for use specifically with Camco Furnaces. These intuitive controllers cut down on training time, simplify process engineering, and increase operator accuracy.

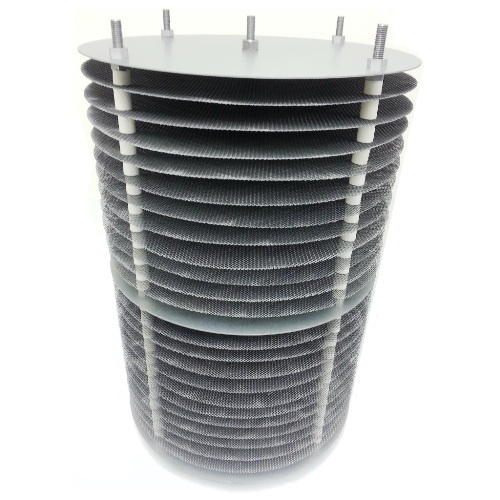

Standard and Custom Fixturing

Run more parts with better thermal conductivity

Browse our existing fixturing, racks and other high-temperature furniture, or ask us about building you the perfect system for your parts. Experts at working with molybdenum, tungsten and technical ceramics, our wide selection of available in-house materials allows us to build just about anything with short lead times.

Broad Range of Solutions.

Let us make the best one for you

Our furnaces are commonly used in these processes:

• Ceramic Metallizing

• Hydrogen, Inert gas, Vacuum and Partial Pressure Brazing

• ABA brazing

• Sintering

• Clean Firing

• Annealing

• MIM Sintering

• Ceramic to Metal Seals

• Glass to Metal Seals

Many options to choose from.

Reliability comes standard

Standard Features:

• Touchscreen Controls

• Tower Indicator Lights

• Mass-Flow Controls (MFC) for all process gasses

• Vacuum Purge

• Exhaust Oxygen Analyzer

• Webserver and FTP functionality for remote monitoring

Options:

• Dewpoint Monitor

• Residual Gas Analyzer (RGA)

• Matching tables and cabinets

• Additional Survey Thermocouples

• Inquire for custom features!

Reliability & Safety Features

Protect the Operator and Equipment

Safety and reliability are always important concerns. All Camco furnaces include standard high quality safety interlocks and features, including:

• Low Coolant Flow

• Low Gas Pressure

• Audible Alarms

• "Purge Assure" logic for hydrogen equipment

• "Rate-of-Rise" leakback tests before every run

• Interlocks for protecting delicate vacuum components

• Chamber, Transformer and Cabinet Thermostats

• Electrical Shunts and Panel Interlocks

• Overtemp monitor with adjustable abort setpoints

• Adjustable Chamber "Safe Access" temperature setpoints