Camco High Vacuum Furnaces

Camco's high vacuum coldwall furnaces are simple to run and easy to program. Run parts in high vacuum or partial pressure atmosphere up to 2100°C. Easily and reliably ramp up to desired temperature in minutes or days, depending on your requirements.

Ideal for vacuum clean firing, active metal (ABA®) brazing, and highly controlled vacuum annealing. Vacuum furnaces are also preferable for other processes involving metals that react poorly when heated in gas, such as titanium or niobium. Partial pressure operation is also an excellent option for ultra-clean brazing of metals with low vaporization points in high vacuum, such as copper and silver.

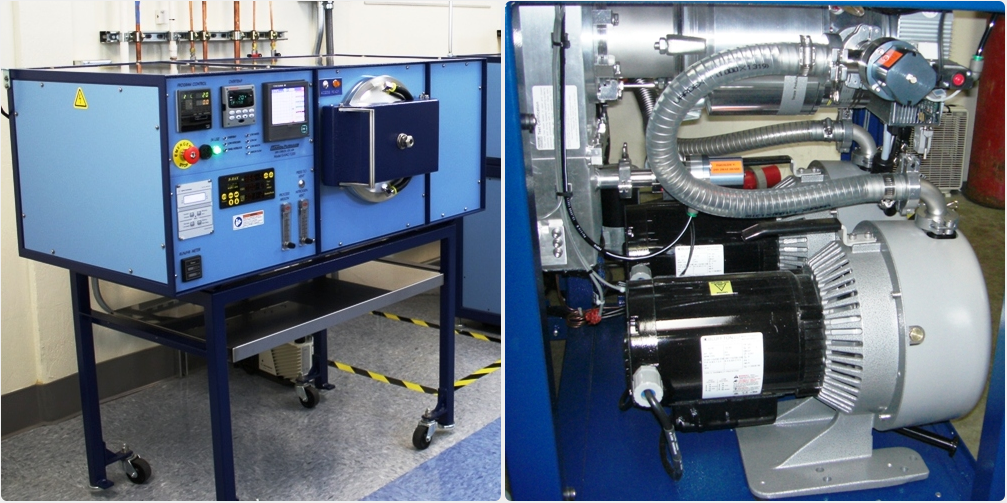

Standard Agilent turbomolecular pumps are reliable, quiet and clean. Typical vacuum down to 10–7 Torr range at ambient. Process vacuum at temperature is usually 10–6 Torr, depending on parts outgassing. Every machine now includes standard PLC touchscreen controls that are intuitive and easy to operate. Cryo pump options are available if better vacuum levels are required.

Other options include: Additional survey thermocouples (flexible type 'K') to aid in process engineering, tower indicator lights to match facility requirements, combination hydrogen operation, auxiliary chamber ports for custom instruments and feedthroughs, and much more. Please let us know if you have any special requirements, we are happy to find ways to meet them.

All of our furnaces are built into a single compact rolling frame that is easy to place in any production environment, clean room or laboratory. Our all-refractory metal hot zones evacuate easily and stay clean for longer. Completely automatic, one button starts the run with no supervision necessary.

As production needs increase, Camco customers can easily move up to a larger unit and hot zone with the exact same easy-to-use programming features and process controls.

Request a Quote Today »

Small

- Model "G" Class Vacuum Furnace

- Benchtop Model, Front or Top Loading. Matching tables available.

- Rapid prototyping or small batch runs

- Footprint:

51" Width x 26" Depth x 20" Height

( 130cm Width x 66cm Depth x 51cm Height ) - Work Zone: ø6" X 10" Depth

( ø15.2cm x 25.4cm Depth )

Medium

- Model "B" Class Vacuum Furnace

- Ideal for expedient small part production. Top loading or hoist raised chambers.

- Compact and simple to move into place.

- Footprint:

65" Width x 28" Depth x 50" Height

( 165cm Width x 71cm Depth x 127cm Height ) - Work Zone: ø12" X 18" Height

( ø30.5cm X 45.7cm Height )

Large

- Model "J" Class Vacuum Furnace

- Electric hoist operated chamber for ergonomic loading of larger parts or batches.

- Multiple hot zones for temperature uniformity

- Footprint:

75" Width x 36" Depth x 110"+ Height

( 191cm Width x 92cm Depth x 280cm Height ) - Work Zone: ø18-20" X 24-48" Height

( ø45cm-50.8cm x 61cm-122cm Height )

Pressure Conversion Table »